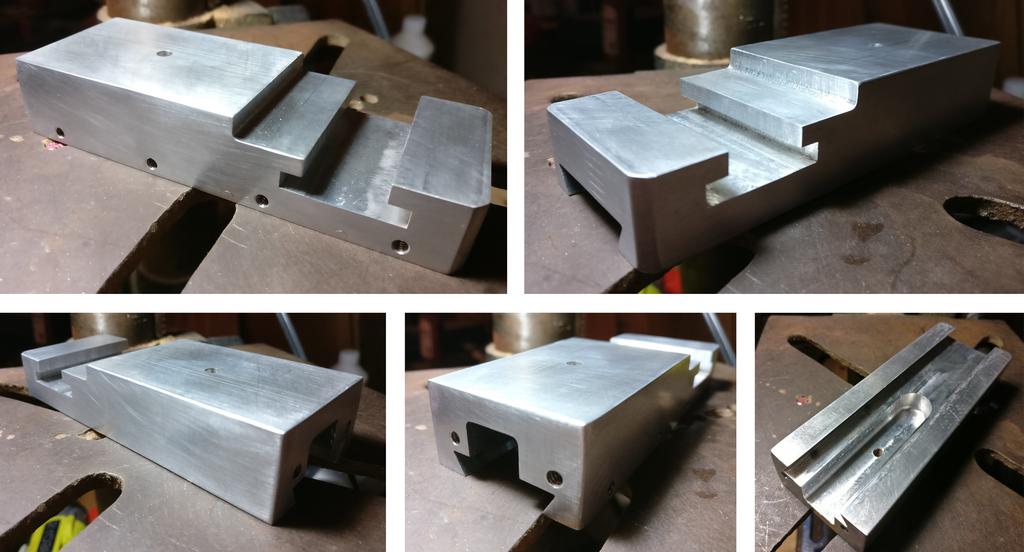

Clamp the swing arm into the block and feed it back and forth on the ways while the boring bar is being driven. Since there would probably be just a few tubing sizes used for the pivot tube a block of aluminum could be bolted to the cross slide with a cap piece on it, and then finish bore that with the bar to get the center height perfect. Then end of the toolbit hole could be threaded to put a screw in to help set the tool to height and hold it in place. Cross drill a hole to take a tool bit with another hole for a pinch bolt. For the swing arm boring what I envision is a bar with centers on each end, just a bit small enough to fit through the bearing inserts (which could be.

0 kommentar(er)

0 kommentar(er)